Progressive Cavity Pumps

Progressive cavity pumps also known as positive displacement pumps or screw pumps, are used to pump heavy, abrasive and low to high viscous fluids like molasses, magma, syrup, Spentwash, potato pulp, cement slurry, mine water, effluent treated waste etc. These are heavy duty pumps working on the principle of Rotary positive displacement system.

Progressive Cavity Pumping Principle

The pumping element comprises of a precision machined single external helix metallic rotor, and a double internal helix elastomer stator. Due to the special profile of the rotor and stator set, a sealing line is formed along the axis of the rotor which is maintained at both static and dynamic conditions.

As the rotor turns within the stator, these cavities progress from the suction to the discharge end of the pump carrying the fluid.

Risansi Manufactures and Supplies Following Types of Progressive Cavity Pumps-

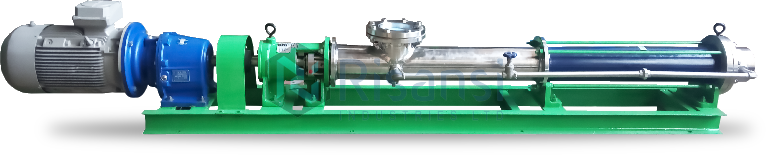

Single screw pumps

We are one of the leading manufacturers and exporters of single screw type progressive cavity pumps. The main component in this pumps is a metal single-threaded rotor which rotates around its principal axis and around the axis of the stator section producing cavities at reduced pressures which move axially from inlet to outlet conveying the fluid at fixed flow rate proportional to the rotational speed.

Capacity- Up to 250m3/hr Head/Pressure- Up to 24 Kg/cm2 Percentage of solids handled- up to 60% -

Auger type screw pump

These pumps are used for transfer of high viscosity, non-homogenous and paste based products like magma, municipal solid waste, shredded food waste etc. Various hopper sizes are available with us. These pumps can give you good pumping performance even with abrasive & fibrous materials in one media.

Capacity- Up to 250m3/hr Head/Pressure- Up to 24 Kg/cm2 Percentage of solids handled- up to 60% -

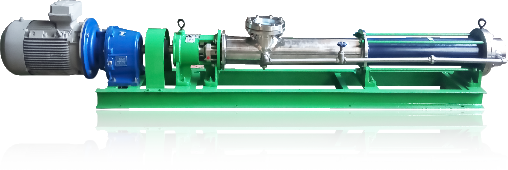

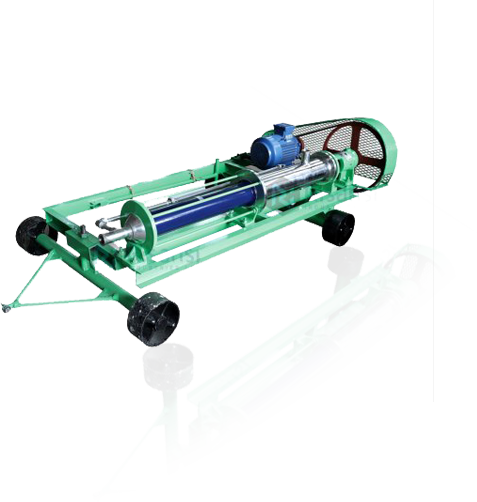

Trolley mounted screw pump

The trolley mounted pump is a perfect skid designed by Risansi. It can perform with any kind of fluid, high or low viscosity media. The trolley mounted pumps are designed for hassle free movement. These pumps can be easily moved from one place to another and most suitable for Sugar, Distillery & Refinery, Food & Beverages, Pharmaceutical & Cosmetics, Food pulp & pastes, paper & cellulose & Dairy industry etc.

Capacity- Up to 250m3/hr Head/Pressure- Up to 24 Kg/cm2 Percentage of solids handled- up to 60%

FEATURES

Open & Closed positions readily visible

Open & Closed positions readily visible Spreading of pipe is not required

Spreading of pipe is not required  Seal protected from accidental mechanical damage

Seal protected from accidental mechanical damage Seal protected from exposure to sun

Seal protected from exposure to sun

Simple one man operation

Simple one man operation Minimal maintenance

Minimal maintenance Positive shutoff of liquids, slurries and gases

Positive shutoff of liquids, slurries and gases Available in flanged/butt-welded connections

Available in flanged/butt-welded connections

Performance

High volumetric and mechanical efficiencies

- Efficient and economical fluid transfer

- Low power consumption and operating costs

Handles all types of media

- Abrasive slurries

- Fluids with solids in suspension

High suction lift

- Can pump from vaccum chambers

Simple Construction

- Fluids with entrapped gas

- Low and high viscosity (1 to 100,000 cps)

- Easy to dismantle and assemble

- No special tools required